Contents

1.2.1 MAJOR ACTIVITIES UNDERTAKEN

ANNEX B Project Organisation Chart and

Contact Detail

List

of Tables

Table 1.1 Summary of Activities Undertaken in the

Reporting Period

Table 2.1 Hourly Average of Parameters Recorded for

CAPCS

Table 2.2 Hourly Average of Parameters Recorded for

CHP 1

Table 2.3 Hourly Average of Parameters Recorded for

CHP 2

Table 2.4 Hourly Average of Parameters Recorded for

CHP 3

Table 2.5 Hourly Average of Parameters Recorded for

ASP

Table 2.6 Hourly Average of Parameters Recorded for

the Standby Flaring Gas Unit

Table 2.7 Quantities

of Waste Generated from the Operation of the Project

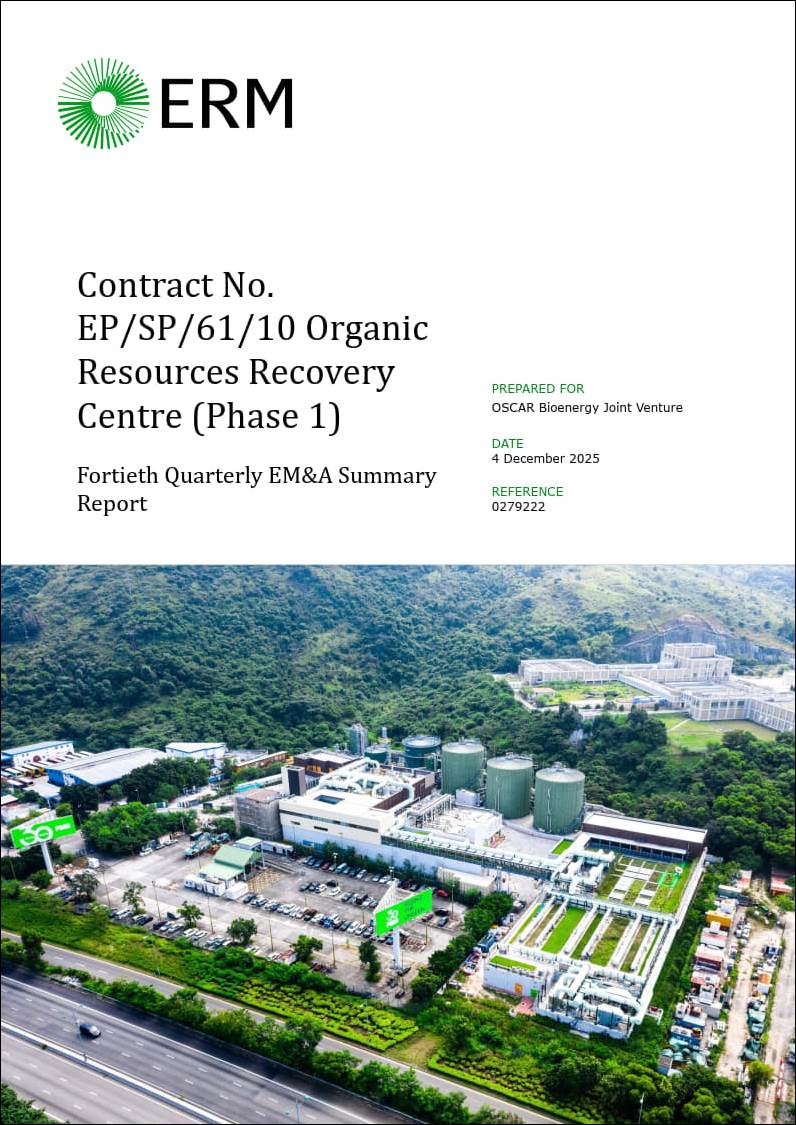

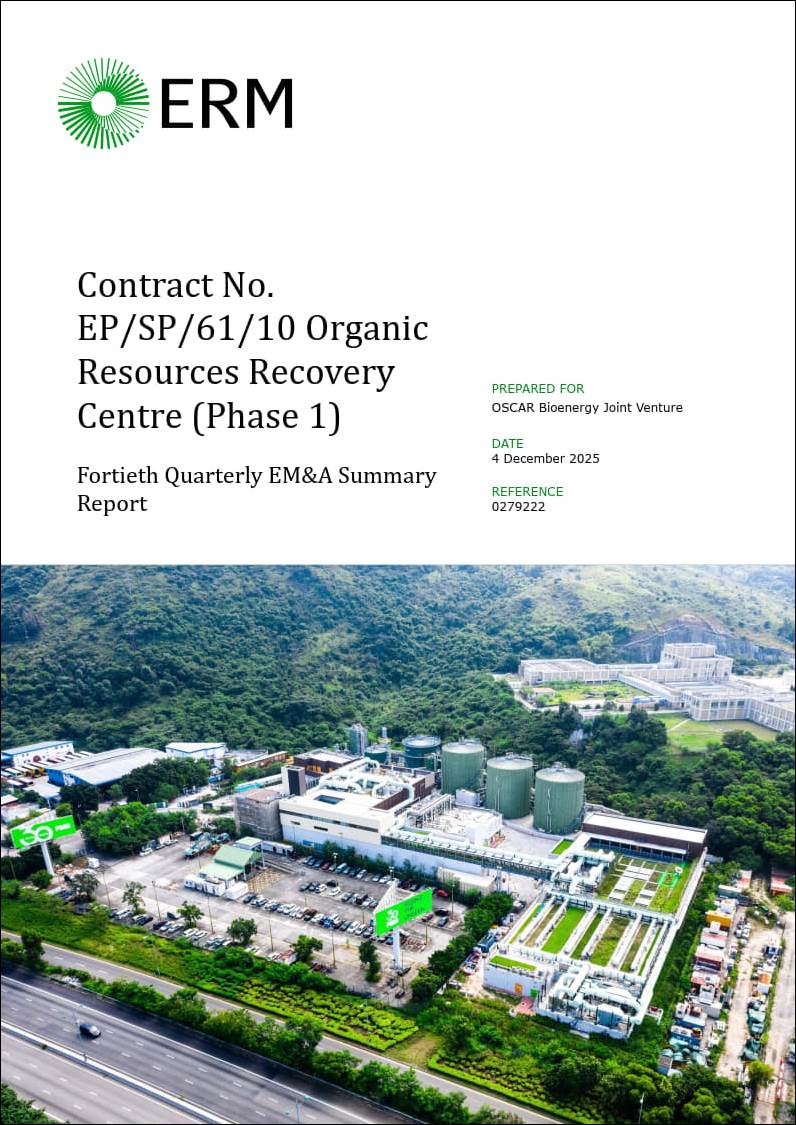

The construction works of No.

EP/SP/61/10 Organic Resources Recovery Centre Phase 1 (the

Project) commenced on 21 May

2015. This is the 40th Quarterly

Environmental Monitoring and Audit (EM&A) report presenting the EM&A

works carried out during the period from 1 March 2025 to 31 May 2025 in

accordance with the EM&A Manual.

Non-compliance of emission limits of

NOx and HCl from CHP1; NOx from CHP3; NOx, SO2,

NH3 and HCl from the ASP; and HF from the Standby Gas Flaring Unit

were recorded during March 2025.

Non-compliance of emission limits of

Dust and Total Odour from CAPCS; NOx from CHP1; NOx from

CHP3 and NOx, SO2, NH3 and HCl from the ASP

were recorded during April 2025.

Non-compliance of emission limits of Total

Odour from CAPCS; NOx from CHP1; NOx from CHP2; NOx,

SO2 and HCl from CHP3; NOx, SO2, NH3,

and HCl from the ASP; and NOx, SO2, VOC, HCl and HF from

Standby Gas Flaring Unit were recorded during May 2025.

Exceedances occurred due to system instability, equipment tripped (stopped and restarted) and normal equipment start up process/ stopping process

(1-3hrs), and ASP tripping.

Exceedances for the air emission limits for the CAPCS, CHP, ASP stacks,

and Standby Gas Flaring Unit were recorded during the reporting period.

No complaint was received during the

reporting period.

The Organic Resources Recovery

Centre (ORRC) Phase I development (hereinafter referred to as ��the Project��) is

to design, construct and operate a biological treatment facility with a

capacity of about 200 tonnes per day and convert source-separated organic waste

from commercial and industrial sectors (mostly food waste) into compost and

biogas.

ERM-Hong Kong, Ltd (ERM)

has been appointed by OSCAR as the Environmental Team (ET) for the construction

phase EM&A programme and the Monitoring Team (MT) for the operation phase

EM&A programme for the implementation of the EM&A programme in accordance with the

requirements of the EP and the approved EM&A Manual.

The Project Site is located at Siu Ho Wan in

North Lantau with an area of about 2 hectares. The facility received an average

of 84.09 to 96.93 tonnes and treated an average of 64.84 to 80.60 tonnes of

source separated organic waste per day during the reporting period.

A summary of the major activities undertaken in

the reporting period is shown in Table 1.1.

Table 1.1 Summary of Activities Undertaken in the

Reporting Period

|

Activities Undertaken in the Reporting Period |

|

�P

Operation of the Project, including organic waste

reception, operation of the pre-treatment facilities, anaerobic digesters,

composting facilities, air pollution control systems, on-line emission

monitoring system for the Centralised Air Pollution Control Unit (CAPCS), Co generation Units (CHP)s and Ammonia Stripping Plant

(ASP), and the wastewater treatment plant; �P

Cleaning of combustion chamber of CHP2; and �P

Cleaning of SBT. |

The concentrations of concerned air

pollutants emitted from the stacks of the CAPCS, CHP, ASP and Standby Flaring

Gas Unit during the reporting period are monitored on-line by the continuous

environmental monitoring system (CEMS). The number of exceedances of the

concerned air emissions monitored for the CAPCS, CHP, ASP and Standby Flaring

Gas Unit during this reporting period are presented in Tables 2.1 to 2.6.

It should be noted that measurements recorded

under abnormal operating conditions, e.g., start up and stopping of stacks and

unstable operation, as well as test runs and interference of sensor, are

disregarded.

Table 2.1 Hourly Average of Parameters Recorded for

CAPCS

|

Parameter |

Range of Hourly Average Conc. (mg/Nm3) |

Emission Limit (mg/Nm3) |

Exceedance Identified |

Remarks |

|

VOCs (including

methane) (a) |

0

�V 67 |

680 |

Nil |

Nil |

|

Dust

(or TSP) |

0

�V 9 |

6 |

Identified

(c) |

System

unstable (e.g., low efficiency) |

|

Odour (including

NH3 & H2S) (b) |

0

�V 975 |

220 |

Identified

(d) |

System

unstable (e.g., low efficiency) |

|

Notes: (a) The VOCs

emission limit includes methane as biogas is adopted, as fuel in the

combustion process. (b) The odour

unit is OU/Nm3. (c) Dates with

Dust exceedances (number of exceedances on that day) were identified on 11(1)

and 27(2) April 2025. (d) Dates with

Odour exceedances (number of exceedances on that day) were identified on 9(7),

10(4), 11(1), 12(3), 13(7), 14(7), 15(2), 16(3), 19(2), 20(11), 21(6), 22(5),

23(6), 24(11), 25(3), 28(2) and 30(2) April 2025; and 2(1), 4(3), 5(4), 6(4),

7(5), 12(4), 13(1), 16(13), 17(11), 18(1), 19(2) and 21(5) May 2025 . |

||||

Table 2.2 Hourly Average of Parameters Recorded for

CHP 1

|

Parameter |

Range of Hourly Average Conc. (mg/Nm3)

(a) |

Max. Emission Limit (mg/Nm3) |

Exceedance Identified |

Remarks |

|

Dust (or TSP) |

0 �V 14 |

15 |

Nil |

Nil |

|

Carbon Monoxide |

0 �V 650 |

650 |

Nil |

Nil |

|

NOx |

0 �V 506 |

300 |

Identified (c) |

System unstable (e.g., low efficiency) |

|

SO2 |

0 �V 45 |

50 |

Nil |

Nil |

|

VOCs (including methane)

(b) |

0 �V 1,397 |

1,500 |

Nil |

Nil |

|

HCl |

0 �V 82 |

10 |

Identified (d) |

System unstable (e.g., low efficiency) |

|

HF |

0 �V 1 |

1 |

Nil |

Nil |

|

Notes: (a) All values

refer to an oxygen content in the exhaust gas of 6% and

dry basis. (b) The VOCs emission limit includes methane as biogas is

adopted as fuel in the combustion process. (c) Dates with

NOx exceedances (number of exceedances on that day) were

identified on 14(5), 15(5), 16(6), 17(1), 18(9), 19(21), 20(24), 21(15),

24(10), 25(10) and 26(16) March 2025; 14(3), 17(6), 19(2) and 24(1) April

2025; and 23(7), 24(24), 25(24), 26(14), 27(13), 28(9), 29(8), 30(11) and

31(1) May 2025. (d) Date with HCl

exceedance (number of exceedance on that day) was

identified on 16(1) March 2025. |

||||

Table 2.3 Hourly Average of Parameters Recorded for

CHP 2

|

Parameter |

Range of Hourly Average Conc. (mg/Nm3)

(a) |

Max. Emission Limit (mg/Nm3) |

Exceedance Identified |

Remarks |

|

Dust (or TSP) |

0 �V 15 |

15 |

Nil |

Nil |

|

Carbon Monoxide |

0 �V 650 |

650 |

Nil |

Nil |

|

NOx |

0 �V 410 |

300 |

Identified (c) |

System unstable (e.g., low efficiency) |

|

SO2 |

0 �V 50 |

50 |

Nil |

Nil |

|

VOCs (including methane) (b) |

0 �V 528 |

1,500 |

Nil |

Nil |

|

HCl |

0 �V 8 |

10 |

Nil |

Nil |

|

HF |

0 �V 1 |

1 |

Nil |

Nil |

|

Notes: (a) All values

refer to an oxygen content in the exhaust gas of 6% and

dry basis. (b) The VOCs emission limit includes methane as biogas is

adopted as fuel in the combustion process. (c) Dates with

NOx exceedances (number of exceedances on the day) were identified

on 22(3) and 23(7) May 2025. |

||||

Table 2.4 Hourly Average of Parameters Recorded for

CHP 3

|

Parameter |

Range of Hourly Average Conc. (mg/Nm3) (a) |

Max. Emission Limit (mg/Nm3) |

Exceedances Identified |

Remarks |

|

Dust

(or TSP) |

0

�V 9 |

15 |

Nil |

Nil |

|

Carbon

Monoxide |

0

�V 277 |

650 |

Nil |

Nil |

|

NOx |

0

�V 682 |

300 |

Identified

(c) |

System

unstable (e.g., low efficiency) |

|

SO2 |

0

�V 71 |

50 |

Identified

(d) |

System

unstable (e.g., low efficiency) |

|

VOCs (including methane) (b) |

0

�V 1,051 |

1,500 |

Nil |

Nil |

|

HCl |

0

�V 126 |

10 |

Identified

(e) |

System

unstable (e.g., low efficiency) |

|

HF |

0

�V 1 |

1 |

Nil |

Nil |

|

Notes: (a) All values

refer to an oxygen content in the exhaust gas of 6% and dry basis. (b) The VOCs emission limit includes methane as biogas is

adopted as fuel in the combustion process. (c) Dates with NOx

exceedances (number of exceedances on the day) were identified on 1(4), 2(1),

4(2), 5(4), 6(5), 7(3), 8(1), 9(5), 11(1), 12(6), 13(17), 14(3), 16(2),

17(14), 18(13), 21(4), 22(6), 23(11), 24(3), 25(1), 27(8), 28(6), 29(8),

30(16) and 31(16) March 2025; 1(14), 2(16), 3(18), 4(15), 5(19), 6(11), 7(6),

8(8), 9(12), 10(16), 11(14), 12(19), 13(23), 14(16), 15(10), 16(16), 17(12),

18(17), 19(16), 20(22), 21(20), 22(21), 23(18), 24(16), 25(7), 26(2), 28(6),

29(15) and 30(2) April 2025; and 3(1), 4(11), 5(17), 6(9), 7(9), 8(19),

9(16), 10(13), 11(9), 12(19), 13(24), 14(23), 15(18), 16(20), 17(24), 18(17),

19(15), 20(18), 21(24), 22(11), 23(18), 24(7), 25(4), 26(5), 27(9), 28(11),

29(21), 30(22) and 31(14) May 2025. (d) Dates

with SO2 exceedances (number of exceedances on

the day) were identified on 3(1), 4(1), 9(1), 10(2), 15(3) and 20(1) May 2025. (e) Dates with

HCl exceedances (number of exceedances on that day) were identified on 3(1),

4(6), 5(3), 6(1), 7(2), 9(1), 10(2), 14(1) and 15(1) May 2025. |

||||

Table 2.5 Hourly Average of Parameters Recorded for

ASP

|

Parameter |

Range of Hourly Average Conc. (mg/Nm3) (a) |

Max. Emission Limit (mg/Nm3) |

Exceedances Identified |

Remarks |

|

Dust

(or TSP) |

0

�V 5 |

5 |

Nil

|

Nil |

|

Carbon

Monoxide |

0

�V 99 |

100 |

Nil

|

Nil

|

|

NOx |

0

�V 1,794 |

200 |

Identified

(c) |

System

unstable (e.g., low efficiency), Equipment Tripped (Stopped and Restarted)

and Normal Equipment Start-up Process / stopping Process (1-3hr), ASP

tripping |

|

SO2 |

0

�V 244 |

50 |

Identified

(d) |

System

unstable (e.g., low efficiency), ASP tripping |

|

VOCs (including methane) (b) |

0

�V 20 |

20 |

Nil

|

Nil |

|

NH3 |

0

�V 340 |

35 |

Identified

(e) |

System

unstable (e.g., low efficiency), ASP tripping |

|

HCl |

0

�V 50 |

10 |

Identified

(f) |

System

unstable (e.g., low efficiency), ASP tripping |

|

HF |

0

�V 1 |

1 |

Nil |

Nil |

|

Notes: (a) All values

refer to an oxygen content in the exhaust gas of 11% and dry basis. (b) The VOCs emission limit include methane as biogas is

adopted as fuel in the combustion process. (c) Dates with NOx

exceedances (number of exceedances on the day) were identified on 1(21),

2(17), 3(20), 4(16), 5(23), 6(13), 7(22), 8(24), 9(10), 10(10), 11(16),

12(5), 21(2), 22(12), 23(15), 24(13), 25(8), 26(12), 27(16), 28(22), 29(22),

30(20) and 31(13) March 2025; 1(23), 2(19), 3(15), 4(24), 5(21), 6(12),

7(15), 8(17), 9(20), 10(21), 11(18), 12(24), 13(24), 14(24), 15(19), 16(23),

17(17), 18(24), 19(24), 20(24), 21(22), 22(21), 23(24), 24(24), 25(24),

26(24), 27(24), 28(21), 29(19) and 30(22) April 2025; and 1(7), 2(2), 3(8),

4(21), 5(13), 6(23), 7(23), 8(21), 9(22), 10(21), 11(21), 12(15), 13(19),

14(23), 15(22), 16(18), 17(23), 18(24), 19(24), 20(16), 21(24), 22(24),

23(23), 24(24), 25(24), 26(19), 27(12), 28(19), 29(19), 30(23) and 31(22) May

2025. (d) Dates with

SO2 exceedances (number of exceedances on the day) were identified

on 25(1) and 26(1) March 2025; 3(1), 19(2), 23(2), 24(1), 28(1) and 30(2)

April 2025; and 1(8), 2(2), 3(8), 4(23), 5(4), 6(1), 9(1), 10(4), 11(17),

12(15), 13(15), 14(21), 15(21), 16(18), 17(19), 18(20), 19(19), 20(16),

21(23), 22(17), 25(1), 28(4) and 29(1) May 2025. (e) Dates with

NH3 exceedances (number of exceedances on the day) were identified

on 1(4), 2(1), 3(2), 5(1), 9(1), 10(2), 11(6), 12(1), 23(10), 24(7), 25(4),

27(3), 28(3) and 29(1) March 2025; 3(3) 7(3), 9(1), 11(1), 16(2), 18(1),

19(6), 21(2), 23(8), 24(3), 25(1), 26(1) and 28(3) April 2025; and 4(2),

6(4), 7(1), 9(3), 10(3), 11(5), 12(2), 13(2), 14(1), 15(7), 17(3), 19(4),

20(1), 22(5), 23(2), 24(2), 25(2), 28(8) and 29(2) May 2025. (f) Dates with

HCl exceedances (number of exceedances on the day) were identified on 25(1)

March 2025; 3(1), 19(1), 23(1), 24(1) and 28(1) April 2025; and 1(6), 2(2),

3(2), 6(1), 9(1), 12(1), 22(4), 25(1) and 28(2) May 2025. |

||||

Table 2.6 Hourly Average of Parameters Recorded for

the Standby Flaring Gas Unit

|

Parameter |

Range of Hourly Average Conc. (mg/Nm3) (a) |

Max. Emission Limit (mg/Nm3) |

Exceedances Identified |

Remarks |

|

Dust

(or TSP) |

0

�V 0 |

5 |

Nil |

Nil |

|

Carbon

Monoxide |

0

�V 12 |

100 |

Nil |

Nil |

|

NOx |

0

�V 1,402 |

200 |

Identified (c) |

Normal Equipment start up process/

stopping process (1-3hrs) |

|

SO2 |

0

�V 62 |

50 |

Identified (d) |

Normal Equipment start up process/

stopping process (1-3hrs) |

|

VOCs (including methane) (b) |

0

�V 5,761 |

20 |

Identified (e) |

Normal Equipment start up process/

stopping process (1-3hrs) |

|

HCl |

0

�V 239 |

10 |

Identified (f) |

Normal Equipment start up process/

stopping process (1-3hrs) |

|

HF |

0

�V 5 |

1 |

Identified (g) |

Normal Equipment start up process/

stopping process (1-3hrs) |

|

Notes: (a) All values

refer to an oxygen content in the exhaust gas of 11% and dry basis. (b) The VOCs

emission limit include methane as biogas is adopted as fuel in the combustion

process. (c) Date with NOx

exceedances (number of exceedances on that day) were identified on 15(6) May

2025. (d) Date with SO2

exceedance (number of exceedance on that day) was

identified on 15(1) May 2025. (e) Date with

VOC exceedances (number of exceedances on that day) was identified on 15(6)

May 2025. (f) Date with

HCl exceedances (number of exceedances on that day) was identified on 15(6)

May 2025. (g) Dates with

HF exceedances (number of exceedances on that day) were identified on 16(4)

and 26(1) March 2025; and 15(6) May 2025. |

||||

No monthly odour patrol was required

to be conducted for this reporting period.

Environmental mitigation measures (related to

air quality, water quality, waste, land contamination, hazard-to-life, and

landscape and visual) to be implemented during the operation phase of the

Project are recommended in the approved EIA Report and EM&A Manual. Monthly

site audits for March 2025 to May 2025 have been carried out to check the

implementation of these mitigation measures. Follow-up actions resulting

from the site audits were generally taken as reported by the Contractor.

The Contractor has implemented environmental mitigation measures recommended in

the approved EIA Report and EM&A Manual.

The monthly inspections of the landscape and

visual mitigation measures for the operation phase of the Project were performed

on 26 March 2025, 22 April 2025 and 30 May 2025, and no non-compliance in

relation to the landscape and visual mitigation measures were identified.

Wastes generated from the operation of the

Project include chemical waste, wastes generated from pre-treatment process and

general refuse. The quantities of different types of waste generated from

the operation of the Project in the reporting period are summarised in Table

2.7.

Table 2.7

Quantities of Waste Generated from the Operation of the Project

|

Month / Year |

Chemical Waste |

Waste Generated from |

General Refuse |

||

|

|

Disposal of at CWTC |

Disposed of at Landfill (a) |

Recycled (b) |

Disposed of at Landfill (a) (e) |

Recycled (c) |

|

March

2025 |

34,800

L (d) |

548.97

tonnes |

0

tonnes |

2.995

tonnes (e) |

0.031

tonnes |

|

April

2025 |

0

L (d) |

616.80

tonnes |

0

tonnes |

2.534

tonnes (e) |

0.039

tonnes |

|

May

2025 |

0

L (d) |

506.36

tonnes |

0

tonnes |

2.765

tonnes (e) |

0.054

tonnes |

|

Notes: (a) Waste generated

from pre-treatment process and general refuse other than chemical waste and

recyclables were disposed of at NENT landfill by sub-contractors. (b) Among waste

generated from pre-treatment process, no metals, papers/ cardboard packing or

plastics were sent to recyclers for recycling during the reporting period. (c) Among

general refuse, 0.002 tonnes of metals, 0.106 tonnes of papers/ cardboard

packing and 0.016 tonnes of plastics were sent to recyclers for recycling

during the reporting period. (d) 34,800 L of

chemical waste (30,000 L of unwanted flocculation agent and 4,800 L of spent

activated carbon) were disposed of at CWTC in March 2025, no chemical waste

was disposed of at CWTC in April 2025 and May 2025. (e) It was

assumed that four 240-litre bins filled with 80% of general refuse were

collected at each collection. The general refuse density was assumed to be

around 0.15 kg/L. |

|||||